Brazing Unveiled: A Peek into the Science and Technique

Brazing, a metal-joining process that involves the use of a filler metal with a melting point above 450°C (842°F), has been a crucial technique used in various industries for several centuries.

While the technique has remained popular, the process itself has evolved significantly due to advancements in technology. Let’s explore the intricacies of brazing, its advantages and challenges, and its role in modern manufacturing.

A Brief History of Brazing

The roots of brazing can be traced back to ancient civilizations. Archaeological findings suggest that the Egyptians were practicing forms of brazing as far back as 3000 BC, using gold and copper. Over the centuries, this technique was refined and adapted, becoming essential for building everything from durable tools and jewelry, to structural components.

The term “brazing” itself is believed to have originated from the Latin word “brasa,” meaning “embers.” This name reflects the method’s reliance on high temperatures to join metals without melting them completely. As the Industrial Revolution spurred technological advancements, brazing gained prominence in numerous fields, including automotive manufacturing, aerospace, and plumbing.

The Science of Brazing

The Process Explained

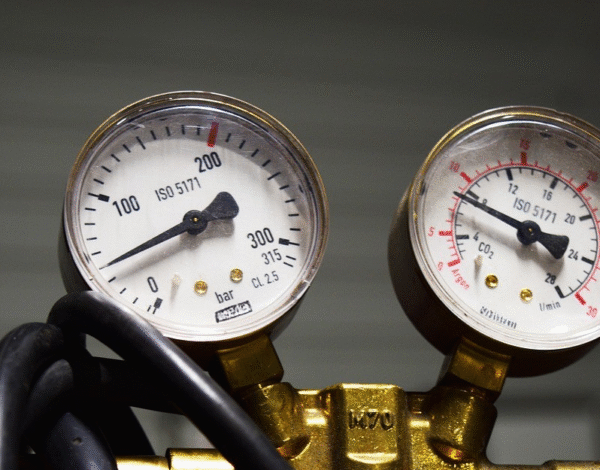

Brazing involves three primary materials: the base metal, the filler metal, and the shielding gas.

The process typically follows these steps:

1. Preparation: The surfaces of the components to be joined must be clean and free of contaminants. This can involve mechanical cleaning or chemical treatments.

2. Assembly: The parts are assembled with a small gap between them, allowing space for the filler metal.

3. Heating: The assembly is heated to a temperature above the melting point of the filler metal, but below the melting point of the base metals. This heating can be done using a torch, furnace, or induction heating.

4. Filling: Once the base metals reach the appropriate temperature, the filler metal is introduced to the joint. It flows into the gap through capillary action, completely filling it as it cools and solidifies.

5. Cooling: After the joint is complete, the assembly is allowed to cool down slowly, ensuring that the metals bond effectively.

Having explored the fundamental principles of brazing, it is essential to examine the various factors that can influence the effectiveness and quality of the brazing process.

Factors Affecting the Brazing Process

Certain factors can influence the brazing process:

– Temperature Control: Precise temperature control is critical. If the temperature is too low, the filler metal may not flow properly; if too high, it can cause damage to the base materials.

– Filler Metal and Shielding Gas Selection: The choice of filler metal and shielding gas are very important and depend on the base materials, desired properties of the joint, and the brazing environment. Common filler metals include silver, copper, nickel, and aluminum alloys. The most common shielding gases are argon, helium, and CO2.

– Joint Design: The geometry of the components can affect the flow of filler metal. Well-designed joints ensure optimal capillary action, filling the joint completely.

Since brazing is used in a wide variety of industries for crucial components, understanding the factors affecting the outcome is vital. This knowledge not only ensures the reliability of the joints produced, but also increases process efficiency for brazing applications.

Brazing Applications

Brazing is used in a myriad of industries, each with specific requirements and challenges:

Automotive Industry

In the automotive sector, brazing is commonly used for assembling components such as heat exchangers, radiators, and fuel tanks. Its ability to join dissimilar metals, such as copper and aluminum, has made it invaluable for complex vehicle assemblies.

Aerospace Industry

The aerospace industry relies heavily on brazing for the manufacturing of heat exchangers, turbine engines, and structural components. The high strength-to-weight ratio resulting from brazed joints is critical for flight safety and efficiency.

HVAC Systems

Brazing is widely used in heating, ventilation, and air conditioning (HVAC) systems for joining copper tubing and components, ensuring leak-proof connections that can withstand varying temperatures.

Electrical Applications

Brazing is often utilized in the manufacturing of electrical contacts and components, where reliable conductivity and resistance to corrosion are essential.

Jewelry

In the world of jewelry making, brazing offers both aesthetic and functional benefits, allowing artisans to fuse various metals and create intricate designs without compromising the integrity of the materials.

Advantages of Brazing

Brazing offers numerous advantages over other joining methods like welding and soldering.

These include:

– Strength: Brazed joints can achieve significant strength, often exceeding the strength of the base materials.

– Dissimilar Materials: Brazing allows for the joining of different metals, enabling the creation of complex assemblies that combine various properties.

– Low Distortion: The lower temperatures involved in brazing compared to welding minimize thermal distortion of the workpieces.

– Corrosion Resistance: Depending on the filler metal used, brazed joints can exhibit excellent resistance to corrosion, making them suitable for harsh environments.

– Cost-Effectiveness: The ability to join dissimilar materials and use less filler metal often leads to reduced production costs.

Challenges in Brazing

While brazing presents numerous advantages, it also comes with its own set of challenges:

– Preparation: Surface preparation is crucial. Any contamination can compromise the quality of the joint.

– Heat Management: Maintaining the correct temperature throughout the process is essential to avoid issues such as overheating or insufficient melting of the filler metal.

– Skill Requirements: Successful brazing requires a certain level of skill and understanding of the materials involved, making training essential for operators.

– Health and Safety Concerns: The use of high temperatures and certain filler metals can pose health and safety risks. Proper ventilation and protective equipment are necessary to mitigate these risks.

The Future of Brazing

As technology continues to evolve, so does the field of brazing. Emerging trends include:

– Automation: Advances in robotics and automation technology are being integrated into the brazing process, enhancing precision, efficiency, and consistency.

– New Materials: The development of high-performance alloys and new filler materials will expand the applications of brazing, particularly in demanding environments.

– Additive Manufacturing: The combination of brazing with additive manufacturing (3D printing) holds promise for creating unique components with optimized properties.

– Sustainability: With a growing emphasis on sustainability, brazing processes are being refined to minimize waste and improve energy efficiency.

Brazing requires a balance of science and technique. Its ability to join dissimilar metals, create strong joints, and offer versatility makes it a cornerstone in various industries. Understanding the intricacies of the brazing process, from preparation to application, allows manufacturers and artisans alike to harness its full potential. As technology progresses, the future of brazing promises even greater advancements, ensuring that this age-old process will continue to play a vital role in modern manufacturing and craftsmanship for years to come. Whether creating jewelry or constructing an aircraft, brazing remains an indispensable method that exemplifies the ingenuity of metalworking.

Shielding Gas and Filler Metal in the Rocky Mountains

It’s important to ensure the shielding gas and filler metal used for the project are compatible. Different shielding gases have different effects on filler metal. At RMA, we consider ourselves a one-stop shop for all your needs. Our team of experts have experience in a variety of industries and can recommend the right metal and gas, as well as provide all the equipment (electrodes, rods, gloves, helmets, jackets, etc.) for your project. Contact us today to discuss your needs. We look forward to serving you with flawless dependability!