Unique Soapstone: The Versatile Marking Tool

Soapstone, a metamorphic rock primarily composed of talc, chlorite, pyroxenes, micas, carbonates, amphiboles, and other minerals, has earned its reputation as a versatile material used in a wide range of industrial applications. Known for its softness, heat resistance, and chemically inert qualities, soapstone is utilized in various sectors, from manufacturing and fabrication to energy production and art.

In the diverse world of fabrication, accuracy and precision are essential for achieving flawless results. Among the many tools used to mark materials – ranging from metal to wood – soapstone’s uniqueness has made it a preferred marking tool in various fabrication processes.

Industrial Uses of Soapstone

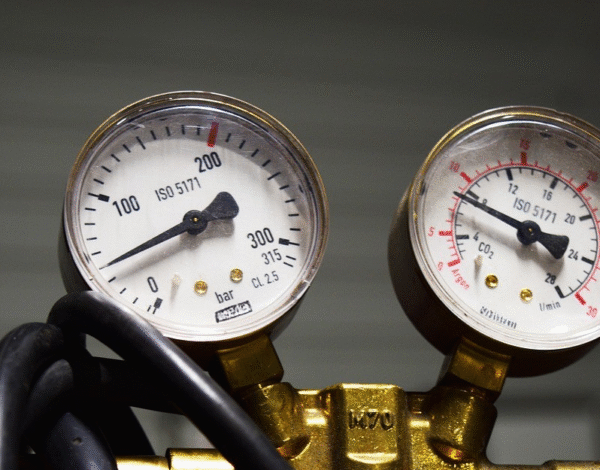

Metallurgical Applications

Soapstone plays a crucial role in the metallurgy industry, particularly for its unique thermal properties. Its ability to withstand high temperatures makes it ideal for applications involving heat and molten metals.

Energy Production

The energy sector greatly benefits from soapstone’s durability and insulating properties. Its capability to withstand extreme heat has positioned it as a critical component in various energy production methods.

Chemical and Pharmaceutical Industries

In the chemical and pharmaceutical sectors, the inert nature of soapstone makes it an excellent choice for manufacturing processes that involve harsh chemicals.

Construction Industry

The versatility of soapstone extends to the construction industry, where it is valued for its aesthetic appeal and performance in building applications.

Electrical Insulation

Soapstone’s non-conductive nature makes it a reliable choice for electrical applications, particularly in insulating materials.

Environmental Applications

With a growing focus on sustainability and environmentally friendly materials, soapstone’s natural composition makes it a favorable choice for eco-conscious industries.

Applications of Soapstone as a Marking Tool

Metal Fabrication

In metalwork, precise measurements and cuts are paramount. Fabricators often use soapstone to mark out dimensions on steel or aluminum, ensuring accuracy during cutting and welding processes. Its visibility against metallic surfaces allows for easy interpretation while working under varied lighting conditions.

Woodworking

Woodworkers utilize soapstone for marking joints, cuts, and patterns. The fine lines made by soapstone can be easily traced with saws or chisels, minimizing the risk of overshooting margins or damaging the wood. Additionally, because soapstone doesn’t leave a permanent mark, it is especially useful for intricate designs.

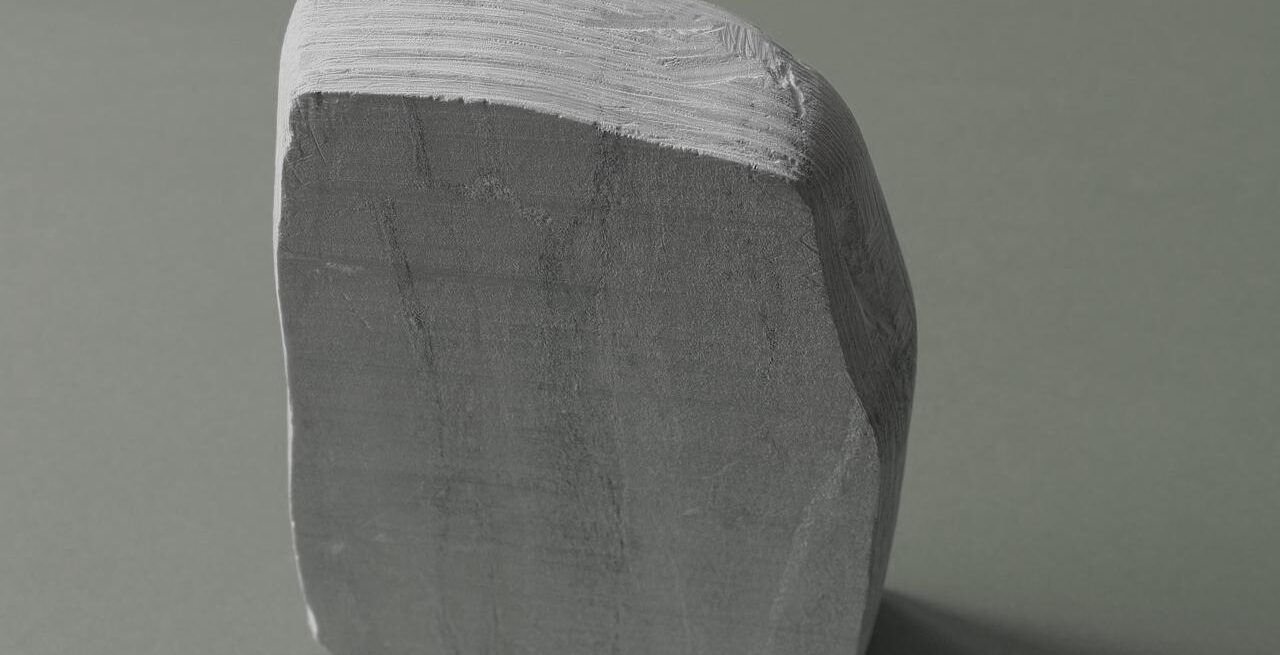

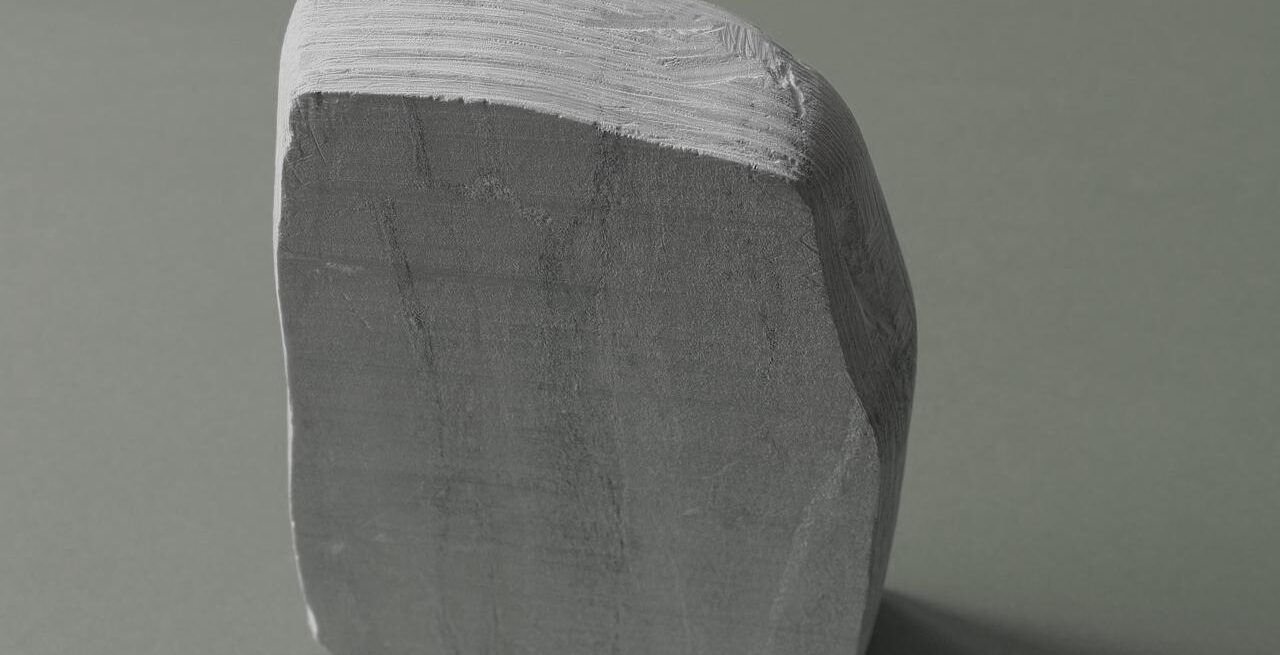

Stone Carving

For stone sculptors, soapstone offers a dual purpose. Not only is it a carving medium, but it also serves as an excellent marking tool to outline shapes before starting the carving process. It allows artists to visualize their designs without worrying about lasting marks.

Glass Cutting

In glass fabrication, marking with soapstone can ensure accurate cuts. It leaves a clean line that can be scored easily, guiding cutting tools for flawless results.

Advantages of Soapstone for Marking

Soapstone offers several advantages in marking applications due to its unique properties. These include: softness and precision, thermal resistance, visibility, and ease of erasure.

– Softness and Precision: One of the primary advantages of soapstone is its softness, which enables it to make clear, easily visible marks on a variety of surfaces, including metal, wood, and stone. Unlike harsher marking tools that can damage surfaces, soapstone is gentle, while maintaining precision, which is vital for intricate work.

– Thermal Resistance: Soapstone’s ability to withstand high temperatures without degradation makes it suitable for applications that demand heat resistance.

– Visibility: Soapstone marks are often white or light in color, which stands out clearly against darker materials. This high contrast makes it easier for fabricators to see their marks, reducing the chances of error when cutting or machining.

– Ease of Erasure: Another benefit of soapstone is its ability to be easily wiped off or sanded away. This quality allows for corrections on the workpiece without causing permanent damage, enabling fabricators to maintain a clean and professional finish.

Tips for Using Soapstone as a Marking Tool

– Choose the Right Softness: Soapstone comes in varying degrees of softness; softer stones will create thicker marks while harder stones will produce finer lines. Select the right type based on your project’s needs.

– Maintain Your Soapstone: Keep your soapstone marking tool in good condition by regularly sharpening or shaping the edges to ensure clean marks. A refined point allows for greater precision.

– Store Properly: When not in use, store your soapstone in a cool, dry place to prevent it from chipping or breaking. A well-maintained tool will consistently deliver better performance.

Soapstone’s unique properties make it an invaluable asset in the fabrication industry. Whether you’re a seasoned fabricator or an aspiring artisan, considering soapstone as part of your marking toolkit could yield extraordinary results and elevate your craftsmanship to new heights. Embrace the art of precision with soapstone and find out how it can transform your fabrication processes.

Soapstone in the Rocky Mountain Region

RMA is a supplier of soapstone in the Rocky Mountain Region. Whether you are operating in metallurgy, construction, or any other industrial sector, consider the benefits that soapstone can bring to your operations. Contact us today! We look forward to serving you with flawless dependability.